Unlock the power of proactive risk management with GQP 4.0! Our software is meticulously crafted to track and address process risks, empowering you to act swiftly and decisively before issues escalate. From planning and design to validation and continuous improvement, GQP offers a comprehensive suite of risk-based tools that revolutionize your approach to quality control. Experience a new level of efficiency and control in your operations with GQP 4.0 – the ultimate solution for process risk management.

Transform the manufacturing supply chain globally with stability, control, and repeatability through the five phases of GQP

Facilitate real-time collaboration and proactive intervention through seamless systems integration and advanced data analytics.

Integrate with Industry 4.0 principles and technologies, leveraging advancements like automation and real-time analytics.

Provide secure, encrypted, and IoT-enabled software solutions to embed process stability, control, and repeatability throughout the product lifecycle

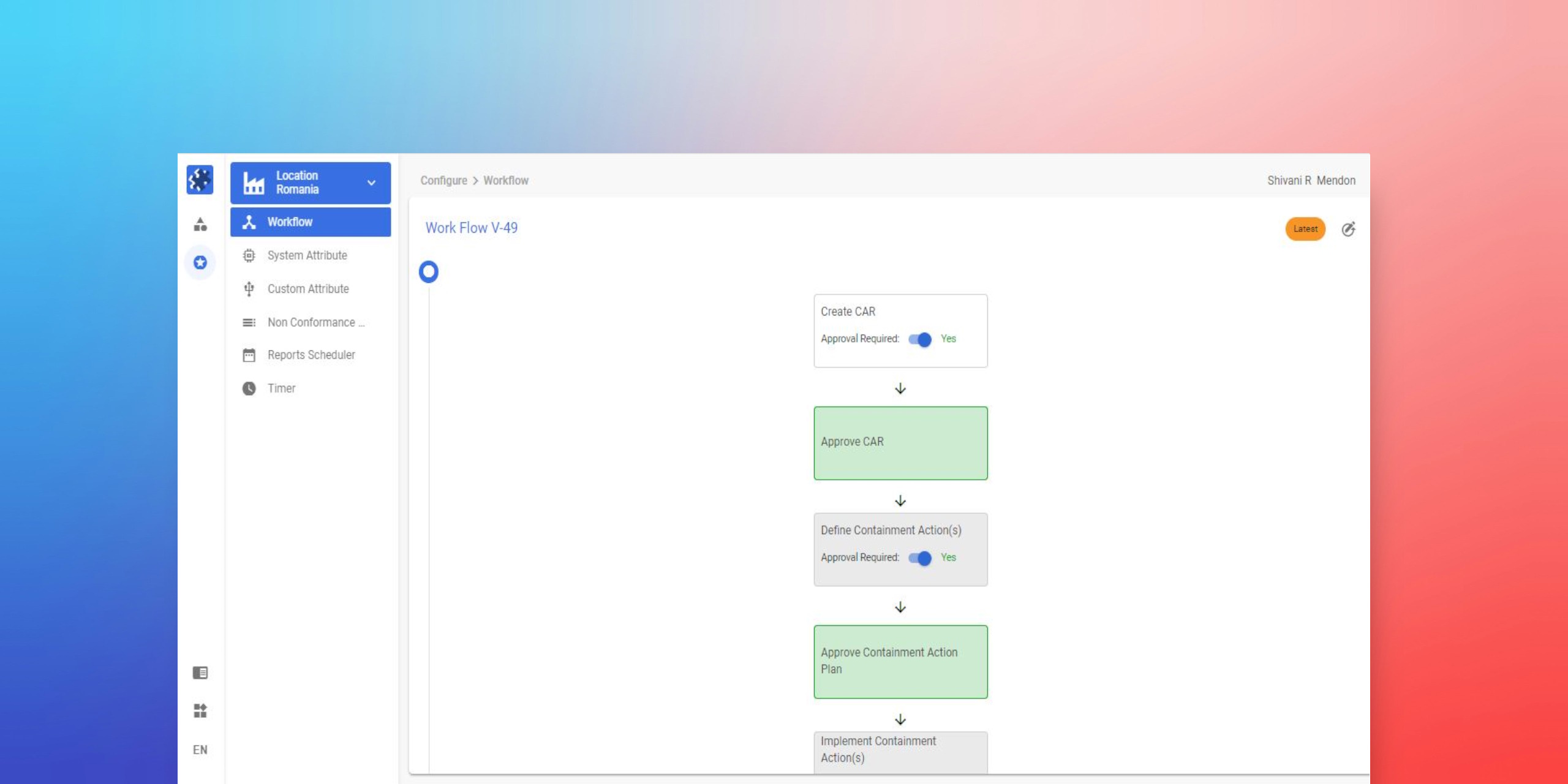

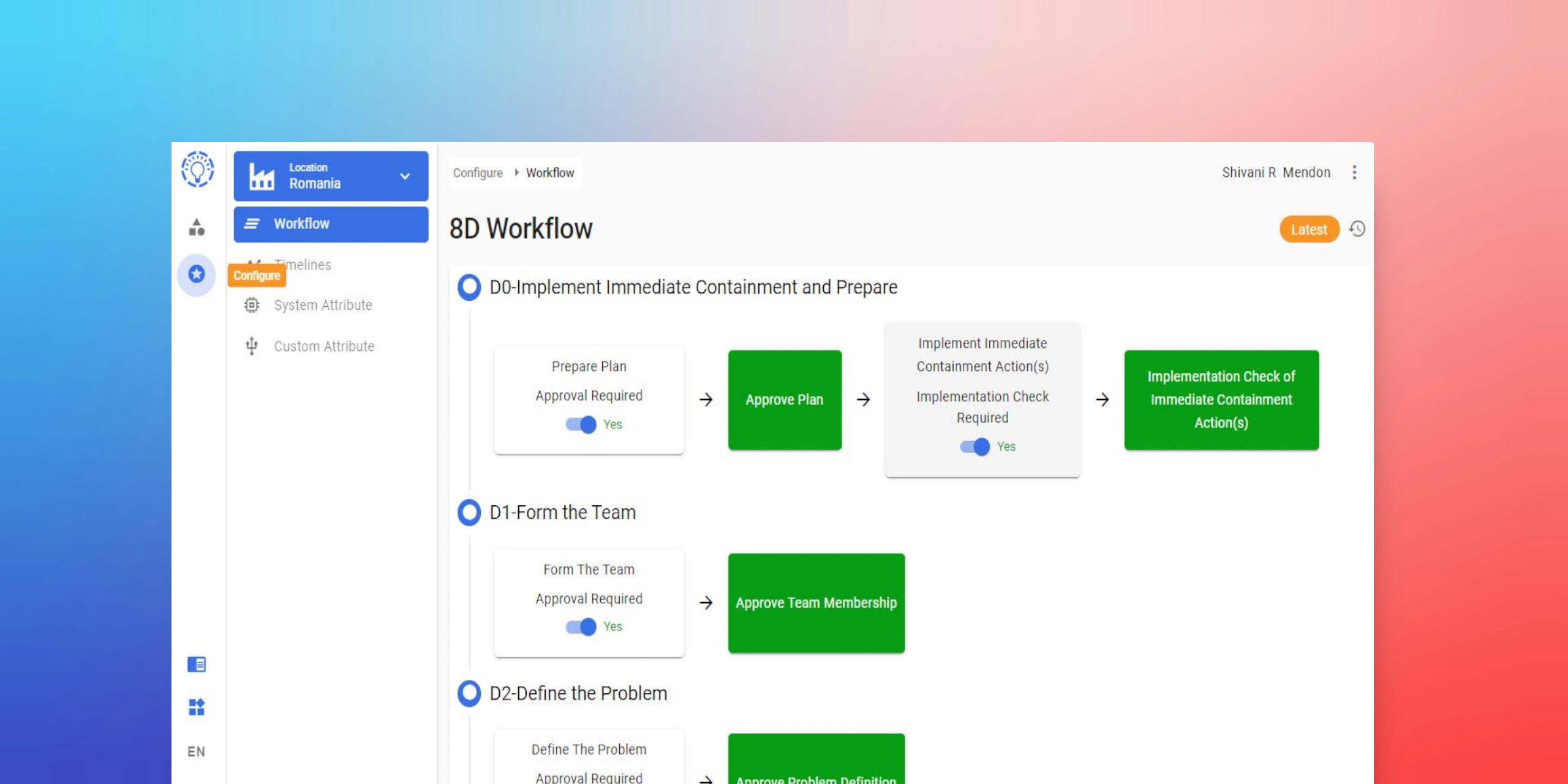

Feature loosely coupled modules for configuration flexibility and scalability.

Offer a comprehensive suite of modules covering all aspects of process risk management, ensuring holistic risk mitigation and operational excellence.

Utilize cloud computing technology for scalability, accessibility, and flexibility.

Offer multi-tenancy architecture for optimized resource utilization and reduced operational costs.

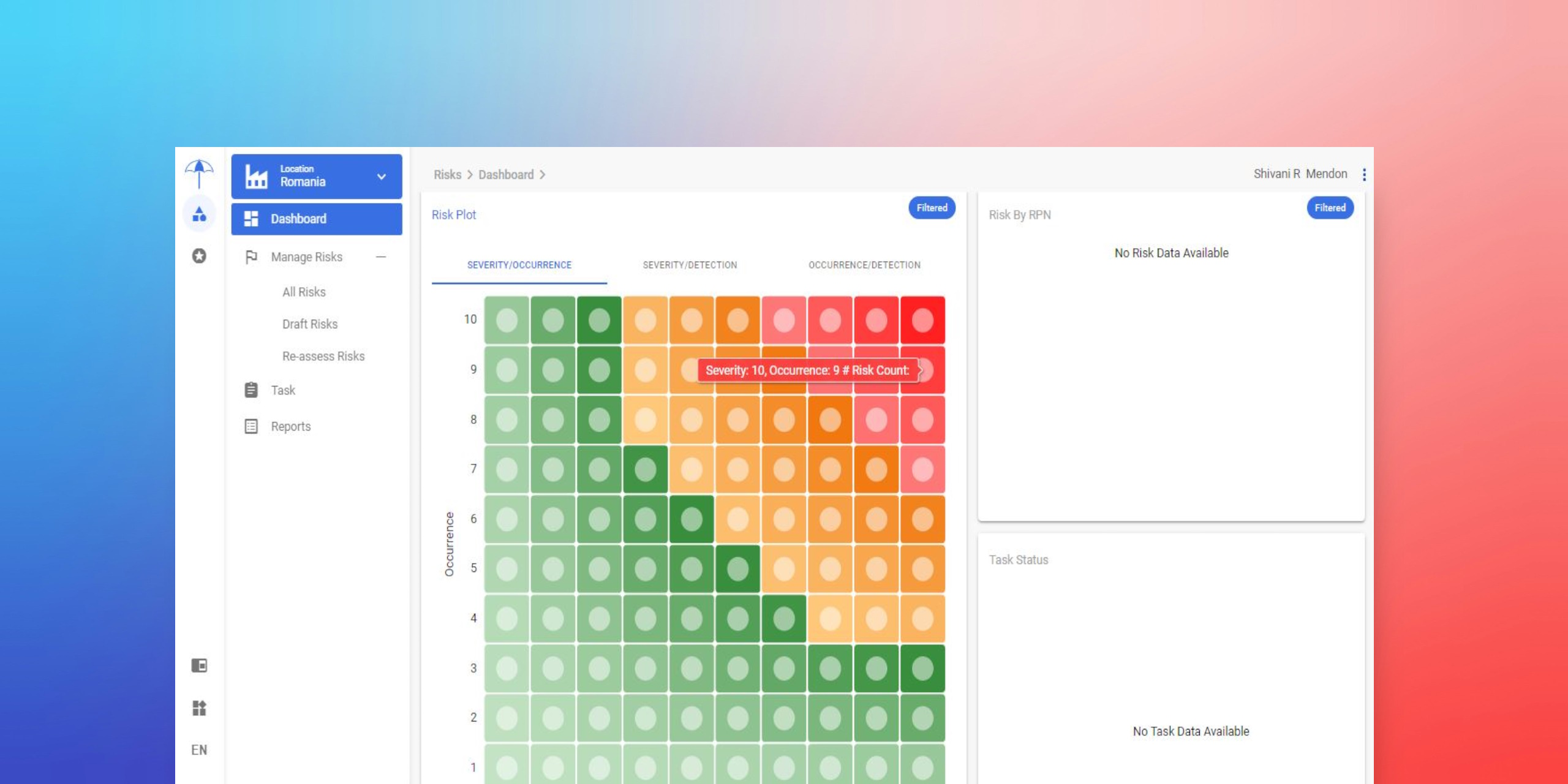

Employ predictive logic and risk-based thinking for proactive risk mitigation.

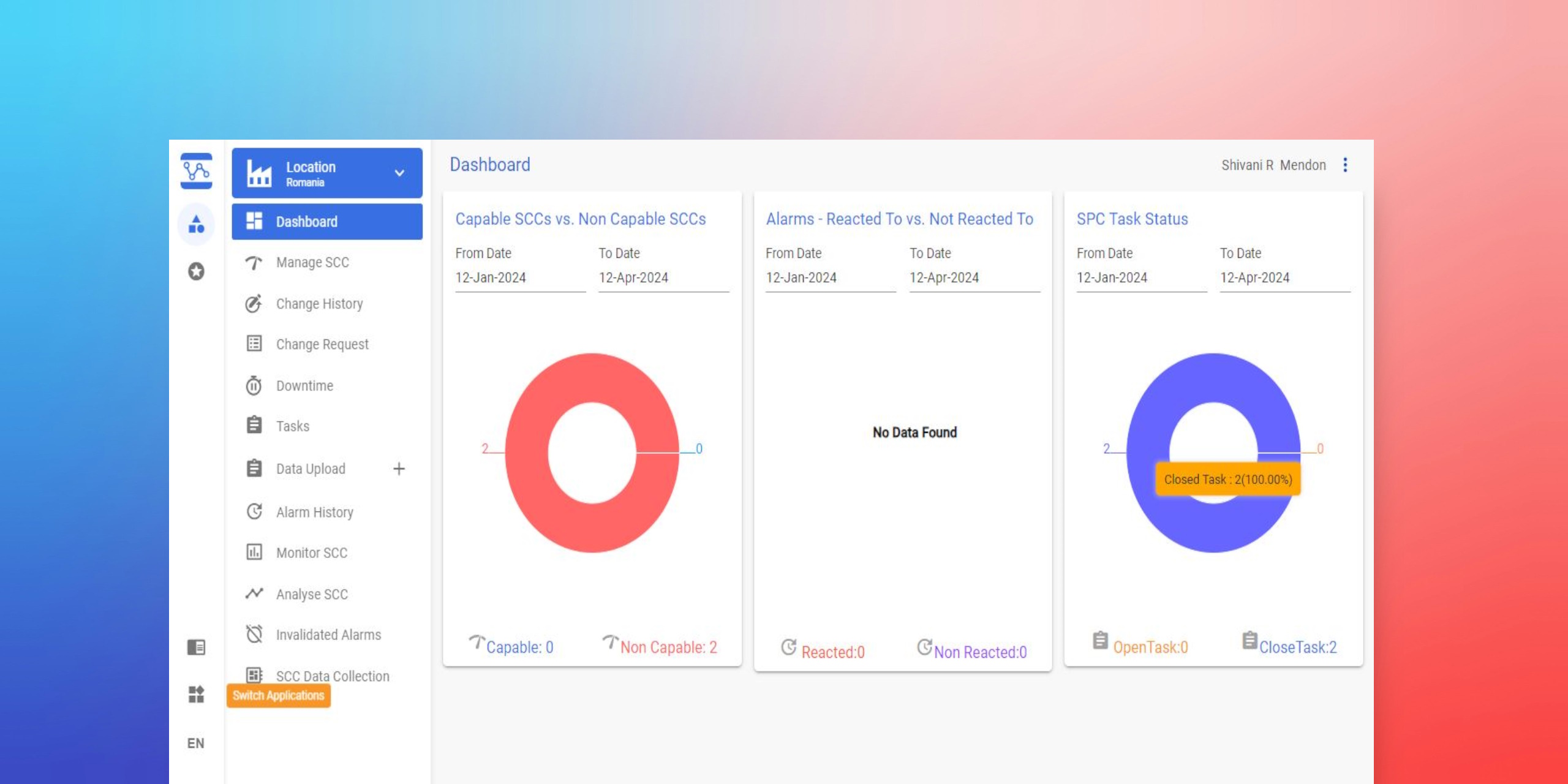

Provide configurable alarms and alerts for timely corrective actions

Utilize statistical methods to monitor and control process variability.

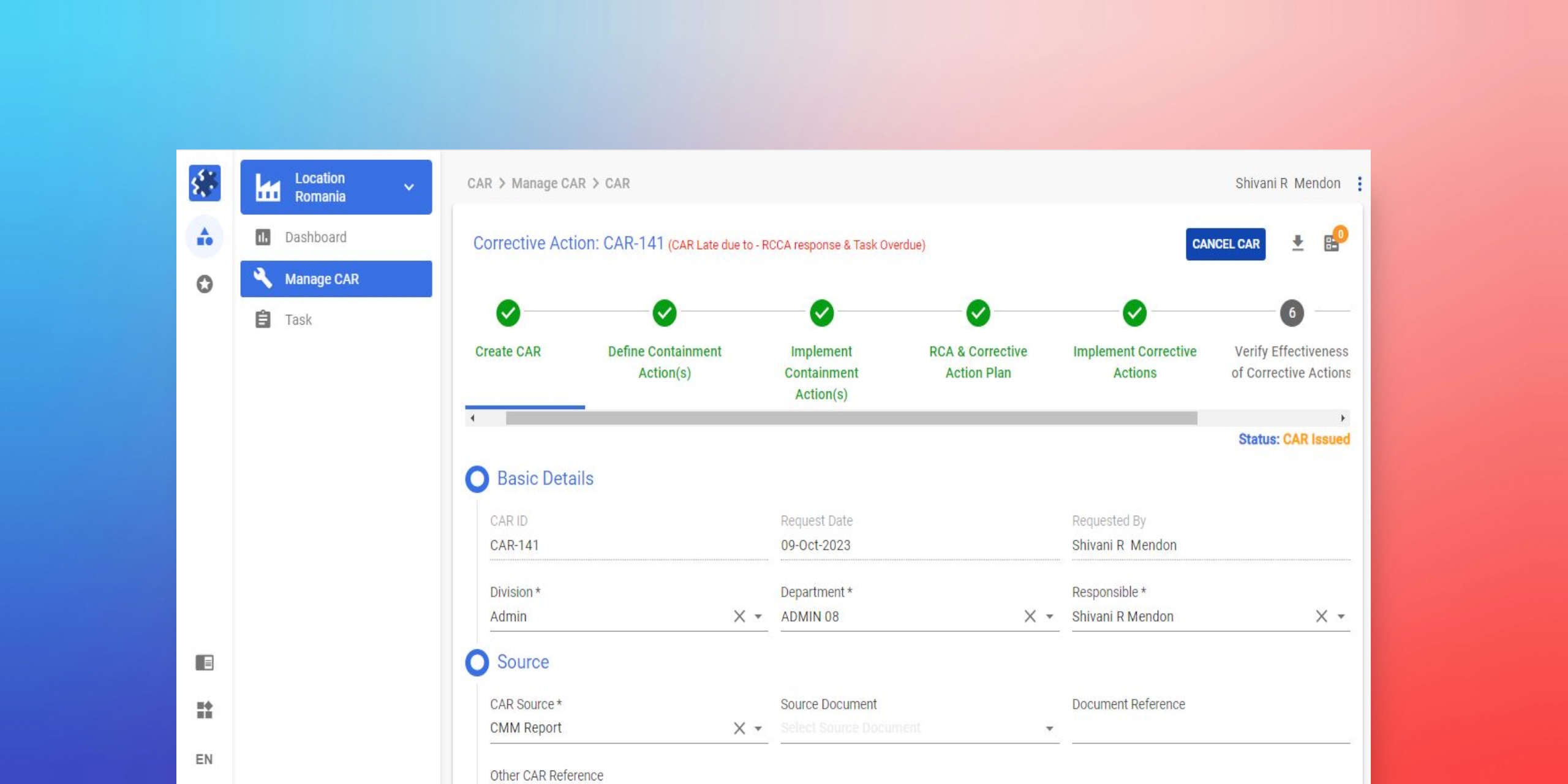

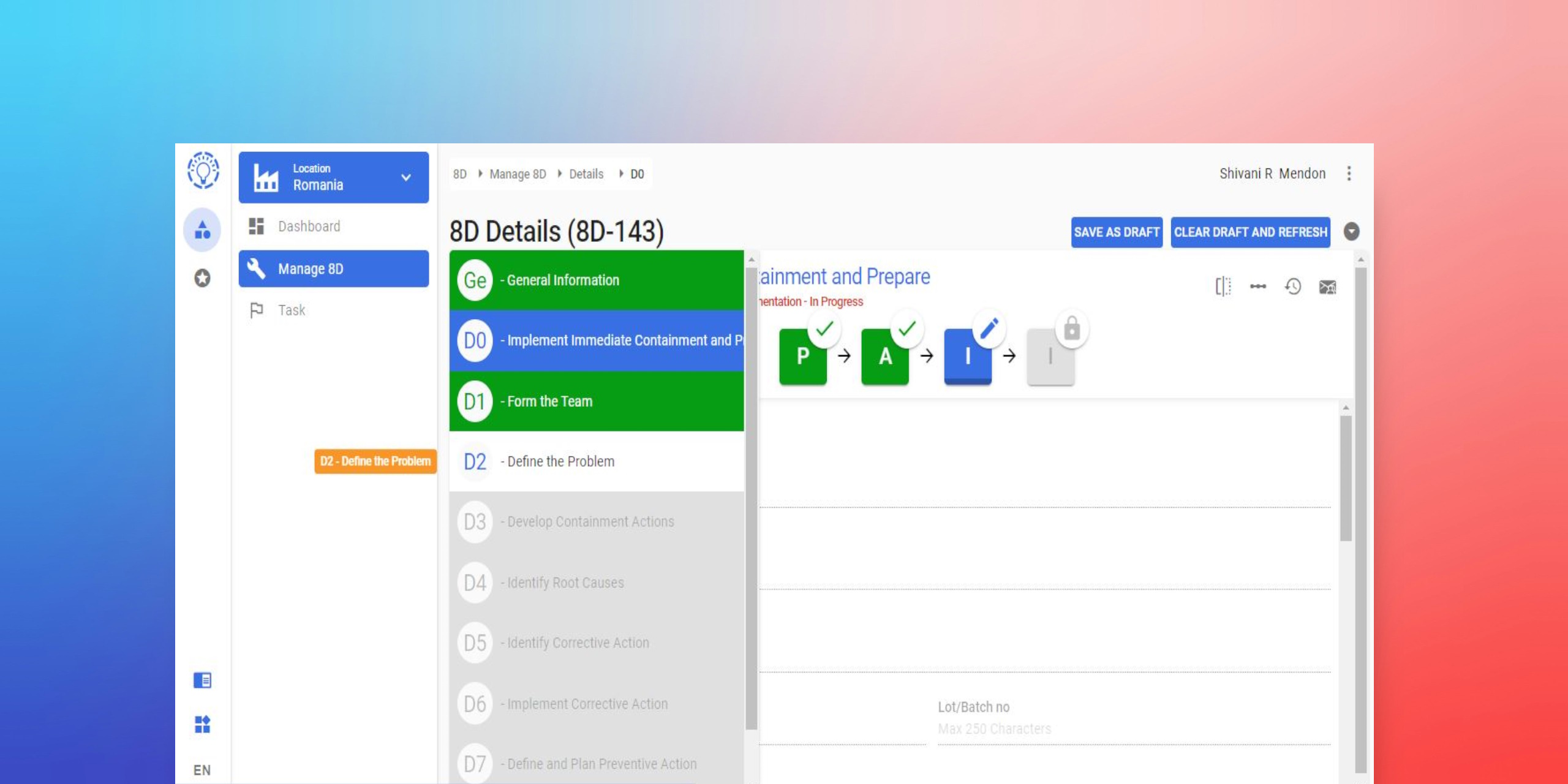

Employ structured problem-solving methodology for resolving complex issues.

Conduct comprehensive analysis to identify potential failure modes and prioritize corrective actions.

Conduct proactive auditing to verify process compliance and identify areas for improvement.

Capture and disseminate valuable insights and experiences to foster continuous learning.

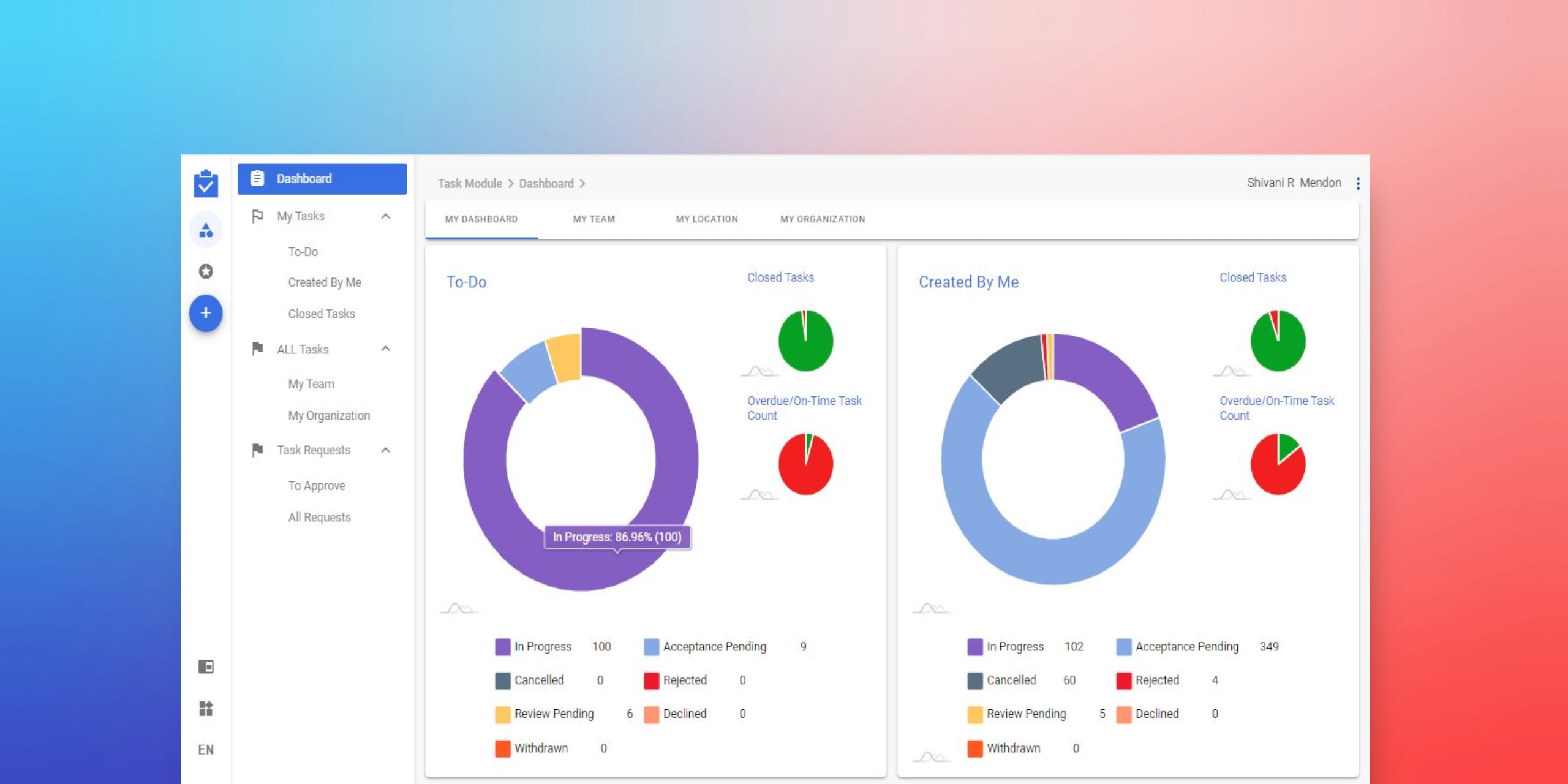

Streamline the process for identifying and implementing corrective actions

Provide a centralized platform for aggregating and consolidating data from various sources.

Systematically assess, develop, and manage employee competencies and skills.

© 2024 Nevtion Technologies | ALL RIGHTS RESERVED